Working with yachts and commercial passenger vessels

JUNE 2019

Over the last few years we have welcomed a number of yachts and commercial passenger vessels for refits and dry-docking at Babcock NZ’s facility in Devonport Dockyard, Auckland. The following examples showcase the work packages we have undertaken for motor yachts, sailing yachts and boutique cruise ships.

Should you have a similar large yacht or passenger vessel operating in Australasian and/or South West Pacific waters, we would be pleased to offer you our project management, design and dry dock services. Please contact us to discuss future plans for vessel survey dockings, refits and equipment upgrade packages.

Expedition motor yacht Senses

The 59m motor yacht, Senses, completed an 11 week dry-dock period in February 2019, which included a 20 year class renewal survey, extensive mechanical equipment repairs and hull painting.

Babcock first docked M/Y Senses in 2015, so this was a very welcome return. A Babcock team was able to visit Senses in Fiji to assist with work specification and planning, so the work package could be set up in a relatively short time-frame. Critical works included the removal of main engines, gearboxes and generators for overhaul, with shipping routes cut through the main deck, and also the overhaul of propeller shafts and fin stabilisers.

The hull was encapsulated to facilitate the preparation and application of a complex paint scheme to the vessel’s topsides and for painting of underwater hull areas.

Other works include the replacement of engine silencers; repairs to stern door; the installation of underwater lights; and, a bow thruster overhaul and with work proceeding on multiple work sites, we were very appreciative of the excellent co-operation and flexibility shown by the Senses captain and crew throughout the project.

Senses encapsulated for hull painting

Senses port stabilizer fin being re-fitted following overhaul

Motor yacht Dream

The 60m Abeking & Rasmussen luxury motor yacht, Dream, dry-docked with Babcock in April 2019.

The work package included hull preparation and application of antifoul coatings and propeller coating, as well as overhaul of sea valves and miscellaneous underwater equipment and tank space survey works.

Dream ready to undock

This was Babcock’s first docking of Dream and our first opportunity to work with Dynamic Yacht Management, the Florida based managers of the vessel and the communications and co-operation throughout the project with both the crew and management company was excellent.

Sailing yacht M5

The 75m single masted sailing yacht, M5, has been dry-docked for hull cleaning, underwater hull painting and for polishing of the topsides for application of a Zytexx ceramic coating.

Whilst in dock, the yacht’s main sail boom was removed for repairs; a new speed log was installed and a propeller control gauge replaced.

M5 Yacht in dry-dock

Explorer yacht Arctic P

The 87.5m explorer yacht Arctic P dry-docked with Babcock in April 2018, her third visit to us.

For 2018 the work list was limited to intermediate survey items and underwater hull preservation.

Arctic P

Previous work packages have included overhaul of capstans and propeller shafts, main engine surveys. Modifications included replacement of existing generator sets with new Deutz BF8M1015MC engines; installation of a new switchboard and command and control cabling; new exhaust systems, fuel lines and installation of new seawater cooling lines.

Want to find out more about our New Zealand dry-dock or ship repair services?

For more information on our services or for other enquires please complete this form.

Caledonian Sky

Babcock was very pleased to dock the 4,200 grt passenger vessel Caledonian Sky in November 2018. The third time the international cruise ship has dry-docked with Babcock confirming the trust and confidence that customers have in Babcock NZ services.

This year’s docking was for a Class Renewal Survey, and our project team worked extensively with the vessel management company Salen Shipping, included ship inspections in Auckland and Darwin, to plan the work package accurately and to ensure that the required work package were completed in the 16 days available within the vessel’s schedule. Repair activities included propeller shaft and stabilizer surveys, structural steelwork repairs, hull preservation and numerous surveys and repairs. For projects of this size, we would normally allow a longer duration, but we were able to achieve the required timeline by assigning additional work teams and employing additional shifts, and a seven day working week.

A strong consideration in the planning process was to achieve the condensed timeline without affecting the quality of our workmanship or in any way compromising ship and personnel safety.

Caledonian Sky – working the late shift

The volume of work required could not have been achieved in the time available without excellent communication and co-operation from Salen Shipping, not to mention the superb effort by Babcock’s project and technical team as well as sub-contractors from across our local supply chain.

Caledonian Sky with stern being high pressure water blasted prior to removal of propeller shafts

Motor yacht – Vibrant Curiosity

The 85m Oceanco built motor yacht Vibrant Curiosity has dry-docked with Babcock for underwater hull repairs and preservation, and for inspection of underwater equipment including; propeller shaft and rudders, hull anodes, anchor chains and lockers.

To remove any risk of contaminating the yacht’s topsides and superstructure whilst spraying the required Intersleek 1100SR antifoul coating system, the underwater area was encapsulated using scaffold and shrink-wrap. The encapsulation, hull repairs and coating preparation and application was completed within a 29 day dry-dock period.

Vibrant Curiosity

Cruise ship – Wind Spirit sailed from Tahiti to dry-dock

The 134m LOA, 5,736grt, motor sailing vessel Wind Spirit, re-positioned from her cruising base in French Polynesia to dry-dock with Babcock for 14 days in 2017.

Babcock’s marine workshop removed the rudder and propeller shaft for survey and also assisted the attending Wartsila technicians with installation of a replacement propeller oil distribution box.

Wind Spirit

Other key dry-dock works included; steel work repairs; sea valve surveys; overhaul and testing of life boat davits and high pressure water blasting and painting of the underwater hull and boot topping. Overseas owner’s specialists also attended the yard period, with the most notable being abseiling specialists to climb the four 62 metre high masts to check and repair stays and rigging.

Motor yacht Dragonfly dry-docking with sailing yacht Sarissa

The 73 m Silver Series motor yacht, Dragonfly, has dry-docked previously for remedial work on the vessel’s propeller shaft bearings and general maintenance.

The propeller shafts and rudders were removed, and repairs carried out on stern tube and rudder stock housings prior to installation of new bearings.

Other dry-dock activities included; fin stabiliser overhaul; underwater hull preservation; application of Prop-speed; anchor chain survey; hydraulic power pack service; structural survey and tender garage floor upgrade.

The 43 m sailing yacht Sarissa shared the dock with Dragonfly for replacement of the operating rams for the yacht’s lifting keel.

Motor Yacht Dragonfly with Super Yacht Sarissa

Luxury motor yacht Tango

The 78m Feadship luxury motor yacht Tango dry-docked in December 2017 for a 14 day work package that included survey of the hull and propeller shaft line as well as underwater hull repairs and preservation.

Tango entering dry-dock

Motor yacht Polar Star

The 63.4m Lurssen explorer yacht, Polar Star, dry-docked with Babcock in October 2017.

The work package included removal of rudders and propellers for survey, inspection of the stern thruster, under water hull preservation, ballast tank cleaning and painting.

Polar Star

Polar Star – Starboard propeller being aligned and re-installed by Babcock technicians

Survey of plimsol and draught marks were completed along with replacement of impressed current system and hull anodes and polishing anchor pockets and fairleads.

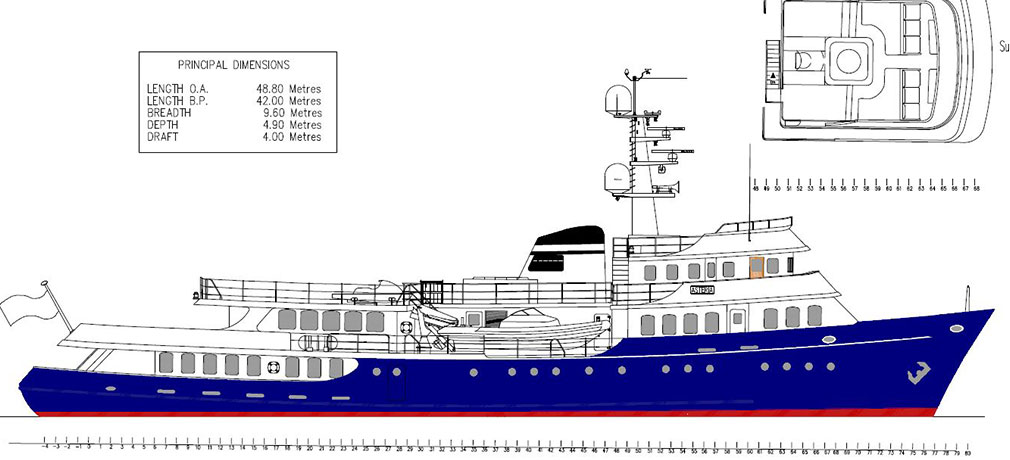

MID – Asteria – 48.8m motor yacht

The motor yacht Asteria completed a 3 month refit period at Auckland’s Silo Marina. Asteria is a long standing customer of MID’s with design work going back to 1998 when a large conversion took place.

For the current refit MID provided design services across several refit items. The vessel was encased entirely in a shrink-wrap scaffold enclosure from masthead to waterline and MID provided stability calculations and checks to ensure stability was satisfactory at all times. A new deck soft patch was fitted to provide an improved removal route for spare parts into the engine room, MID designed and engineered a flush soft patch hatch compliant with class requirements and ensuring structural continuity in the strength deck. MID also provided updates to the vessel Escape and Safety Plan, including using our library of the latest IMO Fire symbols.

For the current refit MID provided design services across several refit items. The vessel was encased entirely in a shrink-wrap scaffold enclosure from masthead to waterline and MID provided stability calculations and checks to ensure stability was satisfactory at all times. A new deck soft patch was fitted to provide an improved removal route for spare parts into the engine room, MID designed and engineered a flush soft patch hatch compliant with class requirements and ensuring structural continuity in the strength deck. MID also provided updates to the vessel Escape and Safety Plan, including using our library of the latest IMO Fire symbols.

Main deck hatch to Engine Room

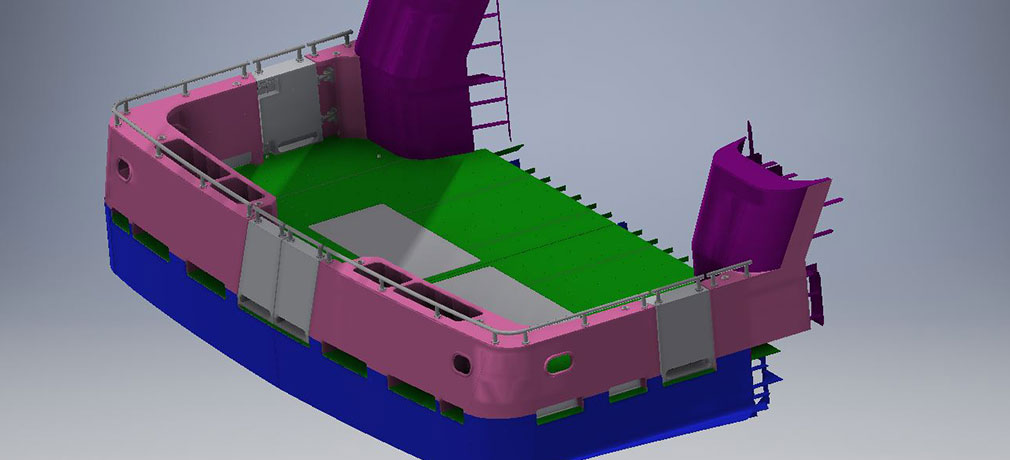

MID – Ourway – 34m motor yacht

The 34m motor yacht Ourway underwent a refit and maintenance period at Auckland’s Silo Marina.

During its stay the Owner engaged MID to produce a concept design for extending the transom area aft by 4m to provide an area for sports fishing. A concept was produced by MID with built-in bait tanks, flush opening bulwark doors, insulated catch tanks and equipment stowage. The transom extension had to satisfy the loadline regulations which limit enclosed compartments the deck level and MID worked with class to ensure compliance.

Ourway 34m motor yacht

A laser scan of the existing transom was conducted, using MID’s in house equipment, to capture the exact shape and layout of the existing area. After the vessel departed NZ on completion of its refit MID produced a detail design drawing package with structural calculations to allow the transom extension to be constructed in a module and then fitted to the vessel. The vessel planned to construct and fit the transom at the next haul out period, which was expected to be in Italy.

Transom extension structural model

Contact us

If you are considering NZ docking or refit projects, or if you would like further information regarding Babcock services complete this form. Alternatively you can contact

Keith Drake Business Development Manager:

Tel: +64 9446 1957

Mob: +64 2192 2335

Email: [email protected]