Welcome – Tēnā koutou

JULY 2021

I trust that 2021 finds you and your teams well, and that business prospects are positive.

The last 12 months or so since COVID-19 emerged have been unusual and challenging times for us all, but in the same way that our customers and marine industry colleagues will have experienced. We have continued providing services to our Maritime customers and ensuring that our staff and customers remain safe whilst doing so. We have, like yourselves, had to adjust our process and systems because of COVID-19, and are particularly proud to have received an Industry Excellence award in partnership with our Royal New Zealand Navy colleagues relating to the systems that we were able to put in place through 2020 to ensure continuity of services at Devonport Naval Base and to minimise the risk of COVID-19 infection to Babcock and Customer personnel.

COVID-19 related Border Restrictions have reduced the number of non-essential vessels visiting New Zealand, including superyachts planning to visit Auckland for the America’s Cup in January and March 2021.

A number of large superyachts have though been able to enter the country for planned maintenance and Babcock New Zealand have continued to be busy both for these and cargo and research vessel projects, and in support of the Royal New Zealand Navy.

We are also proud to report that in April 2021 the New Zealand Defence Force confirmed that a Maritime Fleet Sustainment Services (MFSS) contract is being developed with Babcock. The MFSS is proposed to commence in 2022 for a period of 7½ years, which will enable us to progress our plans with a focus on our long term future and continued success in New Zealand. It will also allow us to continue investment in our local team and engineering capability, including additional apprentices and training.

An overview of our 2020/21 commercial marine projects is included below.

Looking ahead, we are currently finalising our docking schedule for October to December 2021, with a November dry dock window available.

We have extensive prior refit commitments for 2022, which means 2022 dry dock space will be limited. As ever, we would be pleased to discuss dry-docking and vessel maintenance options with you, if not for 2022, then for 2023 and beyond. Please contact Keith Drake for further information.

Finally, it gives me much pleasure to introduce James Morton, who in July becomes the General Manager Maritime of Babcock New Zealand. James will lead all our Maritime related business and takes up the company’s reins as I return to the UK.

Once again, thank you for your continuing support. We value your business and look forward to hearing about your successes and working with you on future projects.

Ngā mihi

Chris Saxby

Managing Director

Babcock NZ

Cement Cargo Vessels dry docked in January / February 2021

A busy start to 2021 with New Zealand’s coastal cement carriers, the 125-metre LOA, 8,745 grt MV Aotearoa Chief and the 130-metre, 6,311 grt MV Buffalo dry-docking in January and February.

MV Aotearoa Chief is operated by China Navigation Company as part of a long-term partnership with New Zealand’s Golden Bay Cement. Aotearoa Chief replaced the cement carrier MV Golden Bay, which docked regularly with Babcock. The 5-yearly Class Renewal Survey docking activities including; water blasting and painting of 5,429 sqm of underwater and topsides hull area; modifications to strengthen the main mast; and overhaul of cement cargo pumps and cargo air slide connections. General survey activities included servicing of main switchboard, engine room fan motors, ship’s crane, engine room oil and air coolers and inspection of underwater equipment.

MV Buffalo, which is operated by Holcim New Zealand, part of global building materials manufacturer LafargeHolcim, was our second January dry-docking. The main work package activities for Buffalo included; overhaul of rudder and steering gear, water blasting and painting of 4,188

sqm of underwater and topsides hull area, and steelwork repairs to hull shell plating, ballast tank plating and pipework, and the ships crane. General survey activities include bow thruster service, bulkhead insulation and outfitting repairs, anchor chain survey and replacement, sea valves, sea strainers and hull anodes.

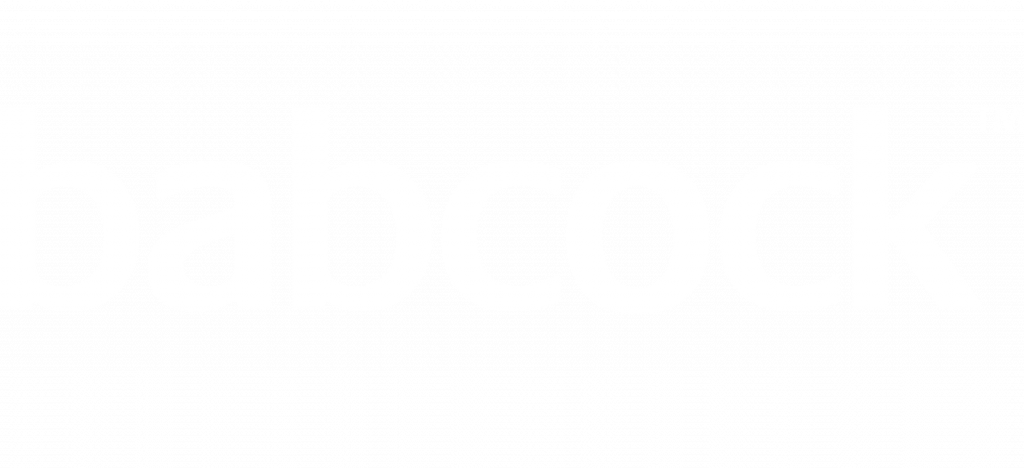

Superyacht dockings

We were pleased to be have been able to provide dry-dock services to three large motor yachts since September 2020. The first was the 67-metre Damen Yachting motor yacht ‘Dapple’, dry-docking for 27 days for overhaul of the vessel’s four fin stabilisers and hydraulic systems. Whilst COVID-19 border restrictions prevented the attendance of original equipment engineers, Babcock was able to successfully complete the stabiliser overhauls due to excellent co-operation between Babcock’s engineering team, m/y Dapple and Quantum Marine Stabilizers. The work package activities also included hull preparation and antifoul; application of Propspeed to propellers,

rudders and thrusters; overhaul of anchor capstans and survey of anchor cables, hull anodes and underwater equipment.

The 81-metre Feadship built motor yacht ‘Air’ dry docked for 25 days, also for overhaul of Quantum Marine fin stabilisers. Other works included hydraulic systems; hull water blasting and preparation for application of Micron 99 underwater hull antifoul; removal of propellers for survey and application of Propspeed; replacement of stern tube seals; survey of sea valves and anchor cables and cleaning and inspection of electrical and ventilation systems.

Our most recent superyacht project was for a 66-metre Feadship built motor yacht, which dry docked in May/June for a 5-yearly hull survey including underwater hull preservation; rudder stock inspection; and removal of Naiad stabiliser fins for inspections. Other maintenance activities for the 1,480 grt yacht included; under water hull valves class inspection; rudder surveys; outboard stern seals and bow and stern thruster inspections and seal renewal; and cleaning and survey of tank spaces.

FNS Vendémiaire Refit completed amidst COVID-19

The 2020 French Navy frigate Vendémiaire dry-docking and refit period was planned for 12 weeks, with improvement works including the upgrade of the vessel’s galley, supporting compartments and refrigerated spaces. Maintenance activities completed included; overhaul of fin stabilisers, propeller shafting and main engines; survey of pumps and electrical motors; repairs to vessel superstructure steelwork and ventilation and engine exhaust systems as well as extensive hull, superstructure and tank painting.

With the COVID-19 situation worsening internationally, Babcock was requested by our customer Chantiers de l’Atlantique (CdA) to complete the refit early, and fortunately as the project team had already been targeting early finish dates, to ensure that the usual emergent work could be accommodated, we were able to complete the refit two weeks early. Babcock are extremely proud of the way in which their team managed the acceleration of work to enable Vendémiaire to depart early. Noting that the early completion would not have been possible without the co-operation of all stakeholders, not least CdA, and Vendémiaire’s managers, officers and crew.

Also of note was the contribution of the Royal New Zealand Navy and Babcock personnel providing shore-side support to Vendémiaire as she completed harbour and sea trials with New Zealand at COVID-19 restrictions in place.

This was the third Vendémiaire Major Refit completed at Devonport and the most challenging to date, in terms of volume of work and available duration.

To paraphrase our customer; completing the refit under COVID-19 conditions was not the end that we imagined, but we had risen to the challenge of making the ship ready to sail on time despite of the work to be completed. The Director of New Caledonian Fleet Support Service also thanked the NZ team involved in completing the Vendémiaire refit “beyond the usual expectations”.

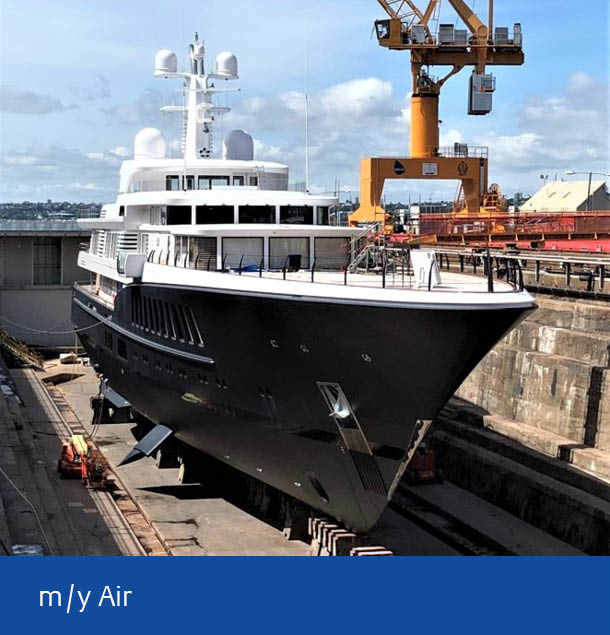

Research Vessel

Tangaroa in dry dock

Babcock dry-docked the 70-metre, 2,291 grt research survey vessel Tangaroa in April 2021 for an intermediate survey, preservation and maintenance work package.

A regular visitor to our dry dock, RV Tangaroa is operated by the New Zealand National Institute of Water and Atmospheric Research who conduct marine and fisheries research in New Zealand’s Exclusive Economic Zone and the waters surrounding Antarctica. The dry-dock critical path was through the preservation works including; underwater hull, topside and aft gantry and removal of rudder and tail shaft for survey and repair. Other works included; fuel tank steelwork repairs; ballast and grey water tank space preservation; hull and anchor cable locker survey; sea strainer and sea valve survey; generator room supply fan motor overhaul and repair to galley fire doors and bulkhead panelling.

Health, Safety &

Environmental update

Collectively, we have done much to improve our approach to Health and Safety in our places of work here at the Devonport Naval Base. Delivering safely has become part of our culture with fewer significant accidents being the result. Here are some of the highlights that we have been working on over the last 12 months:

- A 50% reduction in lost time injuries across the business

- Improving our focus on health and wellbeing with initiatives such as Health Week and training of Mental Health First Aiders

- Introduction of a Respect@Work initiative which aims to build a respectful and inclusive work environment

- Setting up a company-leading focus on continuous improvement, delivering over 60 Six Sigma White Belts and $2 million in savings to our customer over the past year

- Achieving re-certification of our Toitū diamond level accreditation in environmental management

- Launch of our Group-wide Plan Zero 40 carbon emission reduction strategy to allow the Group to reach net zero carbon emissions by 2040.

Jarron Urlic, our Health & Safety Advisor, won the ‘Best Safety Initiative by a Contractor’ category in the New Zealand Defence Force’s Safety Awards. This is well-deserved recognition of Jarron’s achievements in creating an online induction training system that negates the need for face-to-face training by Babcock HSE personnel, and which also allows contractors to complete mandated training before coming on site at Devonport Naval Base. This was crucial during the COVID-19 lockdowns, enabling key suppliers to come onsite while maintaining minimal interaction with other work groups, helping to ensure everyone went home safe every day, and enabling critical work required to support our customers.

FV Tomi Maru in

dry dock

The 69-metre factory fishing trawler Tomi Maru 87 docked with Babcock NZ in June 2020 to undergo a three week dry-docking and maintenance period. Tomi Maru 87 has been coming to the Devonport Dockyard for approximately 20 years for a mix of dry-docking and engine and machinery overhaul projects. During this dry dock period, Babcock provided machinery and outfitting repairs and maintenance services as well as transom and structural steel work repairs. Mechanical works included: servicing fish factory pumps, motors, coolers and separators and survey of sea valves and underwater equipment. Preservation work included underwater hull antifouling, hull topsides and superstructure areas.

Supply Chain update – Amotai

We are very pleased to report that Babcock NZ is now a registered member of the Amotai initiative which aims to increase supplier diversity through the connection of business to Maori and Pasifika owned businesses. We are excited about the opportunities that this initiative will bring to our local New Zealand supply chain.

Marine Industrial Design update

In a busy first half of 2021, MID continued to design and deliver a multitude of diverse and varied projects to many sectors of the marine industry. Despite the challenges of COVID-19 we have continued our growth strategy, and the team now stands at 14 across two offices – Auckland and Whangarei. MID are planning regional expansion to provide support in other centres around New Zealand – watch this space!

Two maritime engineering degree student interns have joined us over their summer break. Our internship program is joined up with our parent Babcock to foster and encourage marine engineering degree qualified employees. This year, working with the Royal Institute of Naval Architects, we were able to announce a joint bursary to sponsor one student each year and to support their costs.

A sample of some of our recent projects is shown below and demonstrates the diverse nature of our work.

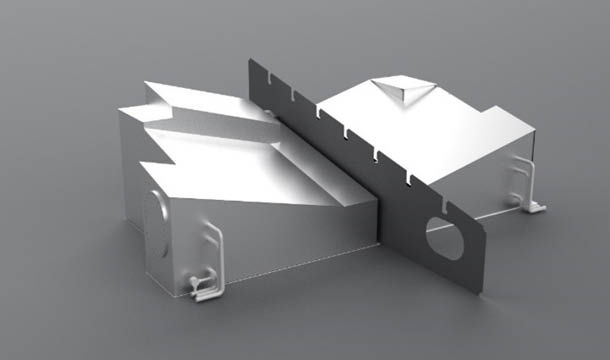

Superyacht refit kerosene tanks

We continue to support superyacht and commercial vessel refit activity in New Zealand. Working with local yards and trades, we were able to provide fully detailed design drawings for installation on board which meets class and flag state regulations, and which provides all the practical operating systems that the vessel and crew require.

For a 60 metre motor yacht, we have provided design and technical support for installation of new petrol and kerosene tanks. These tanks, filled with low flashpoint fuel, require stringent measures to ensure the vessel safety. The tanks must be enclosed by a secondary cofferdam to prevent gas escape, which can be challenging when trying to install tanks into tight confined spaces on board, and especially when the tanks must be constructed in situ.

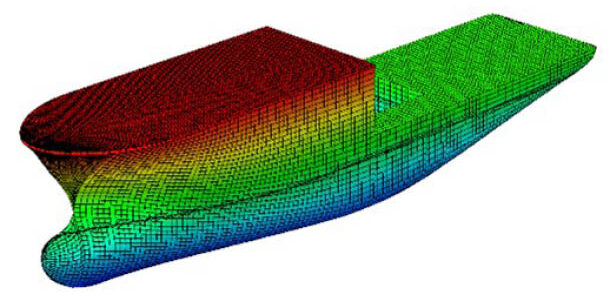

MID have undertaken a comprehensive seakeeping analysis for a customer, to provide operating conditions guidance for in transit, at work site and survival modes. The guidance includes limiting parameters for variables including motion sickness index, prop emergence, bow slamming, deck wetness, accelerations at crew operating positions/cargo locations/crane operations.

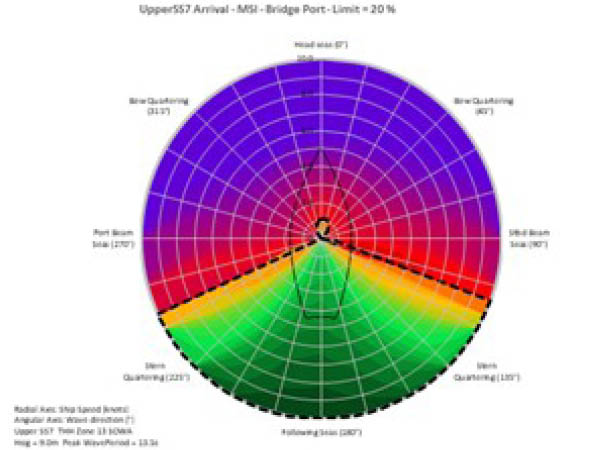

We have developed a unique method of presenting this data, taking the comprehensive and detailed output and transforming it to an easily read polar plot that can be used directly by the crew to confirm operating limits at a matrix of operating conditions. This includes vessel headings 0 to 360 degrees, a range of vessel speeds and a range of expected sea states and wind speeds.

A typical plot is shown, for motion sickness indication, located on the bridge port side, with a range of ship speeds (0 knots at centre, 10 knots at the edge) , in Sea State 7, green indicating no sickness, and red to purple indicating higher probability of sickness.

MID continues to provide Naval Architectural services in support of Babcock NZ’s dry docking and commercial refit services and Babcock’s In Service Support Contract with the Royal New Zealand Navy.

For any enquiries or more information regarding MID, please contact:

Jason Smith MID Manager MRINA C.Eng

Tel: +64 (0)21 020 36 438

E-mail: [email protected]

www.marinedesign.co.nz

Download print versions

Ship repair and marine engineering enquiries

If you are considering NZ docking or refit projects, or if you would like further information regarding Babcock services complete this form. Alternatively you can contact

Keith Drake Business Development Manager:

Tel: +64 9446 1957

Mob: +64 2192 2335

Email: [email protected]